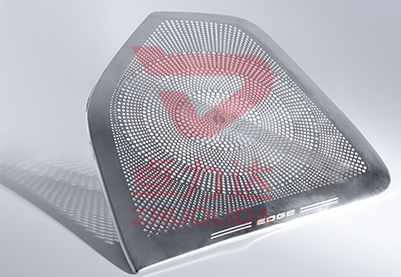

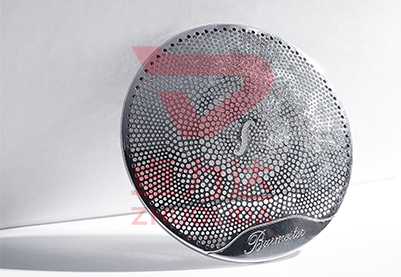

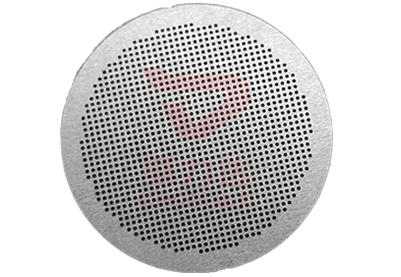

Etched Microporous filter

- Automobile

- electronics

- electrical appliances

- medical precision filtration parts

- Low mold opening cost, can be changed according to the designer's design requirements for any industrial screen mesh, low cost.

- Able to achieve etching microporous filter edge metal surface half engraving, increase the company LOGO, to achieve branding raw.

- No burr, no pressure point, no deformation of the product, no change of material properties, no influence on the function of the product.

- Both thick and thin materials can be processed equally to meet the requirements of different assembly components.

- Almost all metals can be etched, and there are no restrictions on various pattern designs.

- Manufacture of metal parts that cannot be completed by various types of machining.

For more than twenty years, Zhuolida has continued to plow deep and innovate in the field of etching. Established in 1999, the company is dedicated to etching processing, technological innovation, research and development.We have been concentrated in the production and sales of stainless steel, titanium alloy, copper alloy, molybdenum, nickel-based high-temperature alloy and other materials.

We have passed ISO 9001 quality management system certification and ISO 14001 environmental management system certification, automotive industry IATF 16949 certification, high-tech enterprise certification, etc. And we have been cooperating with famous colleges and universities to set up joint laboratories and special etching solution formula development.

French imports of multiple roll-to-roll exposureEquipment, automatic etching solution addition system and liquid regeneration system are introduced from Japan to ensure stable equipment operation, stable etching data and stable quality in the roll-to-roll production metric process.

Nantong has built its own production base and cultivated all kinds of metal etching process personnel with heart and soul in roll-to-roll etching.We continue to practice and research in the field of roll-to-roll etching, and purchase roll-to-roll etching product winding and unwinding equipment, in-line deflection correction equipment and in-line measuring instruments to protect product quality while striving to provide total solutions for our customers.

Zhuolida Group has three production bases, Shenzhen Zhuolida, Kunshan Zhuolida and Nantong Zhuolida, with a combined area of more than 40,000 square meters. And we have been involved in various metal etching, roll-to-roll plating, anodizing, laser cutting, test fixtures and vacuum diffusion welding and many other fields. We have more than 20 conventional, imported and customized non-standard precision etching lines and many roll-to-roll continuous plating lines to meet capacity of etched metal gaskets while providing various metal surface treatment service.