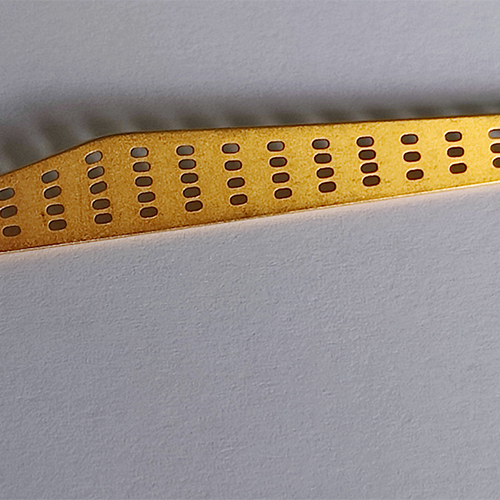

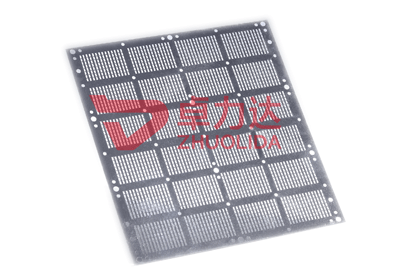

Ceramic Laminates

- Ceramic stack etching

- mainly used in the processing and manufacturing of printed circuit boards

- widely used in televisions

- radios

- computers

- mobile communications and other electronic products

Show picture

1.The company has passed theISO9001 international quality certification, ISO14001 environmental management system certification, IATF-16949 automotive quality management system certification (raw material testing + process inspection + shipping inspection, heavy quality inspection, product quality assurance. Domestic major well-known manufacturers cooperation, yield rate far beyond the peer standard, with stable, high-qualityRaw material purchase channels.

2.Sample production: Equipped with a sample production team, finished within three working days.

3.Our company has 3 manufacturing bases in Shenzhen, Nantong and Kunshan, with a daily production capacity of 5000+㎡, strong technical force (8 senior R&D engineers, 16 engineers, 20 technicians), and the company has advanced production equipment of international famous brands, such as the etching line of CHEMCUT from the United States, the light painting machine from Israel, and the automatic roll-to-roll exposure machine of AUTOMA from France, which provide hard guarantee for production stability.

4.Delivery method: safe, beautiful, environmentally friendly bundle way, 24-hour non-stop delivery (with truck driver delivery), if you need express delivery can arrive within 48 hours, in our cooperation with the express company is SF Express.

5.After-sales service:Customers to our companyThe company will, upon receipt of the customer's objection, raise quality objectionsIf the problem needs to be solved on site, we will send professional technicians and quality personnel, and we will not withdraw the service personnel until the quality problem is solved, and we will file the quality problems and the results of the etching product feedback for each customer.

6.We have obtained national environmental protection approval and discharge permit, and built our own sewage treatment system with 24-hour online monitoring and regenerative circulation system to ensure the stability of the chemical water and improve the yield rate, so that the chemical water can be recycled and truly achieve environmental protection, energy saving and emission reduction. Self-built perfect sewage treatment station, 24-hour online monitoring, wastewater treatment and recycling, to achieve energy saving and emission reduction.

Customer we are doing our best to provide our bestservices to our customers with competitivetech solutions and high quality products,Zhuolida has won wide recognition from ourcustomers in all kinds of industry, andthis have laid a solid foundation for Zhuolida to be an leading brand in etchingindustry in China and a reputablemanufacturer |  |

| Technology Zhuolida is an etching factory in China with varietiesof process, our company process techniques includechemical etching, laser cutting, EDM, stampingelectroforming, electroplating, electrophoresis. |

Enviroment We have self-built sewage treatment system,the wastewater reuse rate reaches 40% |  |

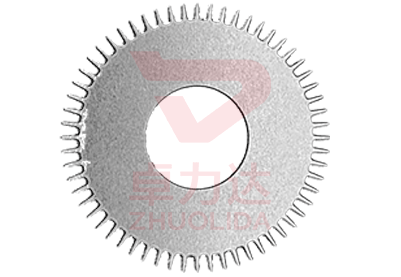

Shenzhen Zhuolida Electronics Co.We are a one-stop high-end precision etching solution provider, specializing in metal etching, precision metal etching, mesh etching, gasket etching, titanium etching, roll-to-roll etching, stainless steel etching processing and other businesses. zhZhuolidaAllEtching of ceramic laminatesThe factory are after production inspection, quality inspection, warehouse verification, layers of control, quality trustworthy! The company was established in Shenzhen Fuyong Huafa Industrial Park,Building areaMore than 6000 square meters, modern plant as well as production and experimental and testing equipment. Key equipment includes: imported etching production line, constant temperature and humidity dust-free operation room, exposure machine, developing machine, secondary measuring instrument, automatic de-filming production line, etc.

Zollida offers:Ceramic Laminate|Etching of ceramic laminates|Ceramic LaminateEtchingProcessing

Shenzhen Zhuolida Electronics Co. https://www.zldsk.com

Address:Huafa Industrial Park, Fuyong Town, Baoan District, Shenzhen City, Xinhe Village, Fuyuan RoadBuilding A3

ContactPhone:0755-2708-8292