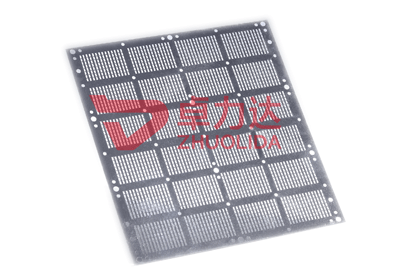

Mask Fixture

The coating fixture is a kind of fixture for wafer cleaning and vacuum coating made of metal stainless steel material through chemical etching and vacuum diffusion welding according to customer needs.

Application area

- Size backlight

- display screen

- car display

- street lamp

- home lighting

- industrial lighting

- headlight

- square lighting

- etc.

Product features

- Low mold cost and short cycle time for the production of the template. Products can be changed according to the customer's design requirements.

- New product filter etching design and development change flexible, and low cost. We can realize the metal surface of the semi-etching engraving and engrave the company LOGO to achieve branding birth.

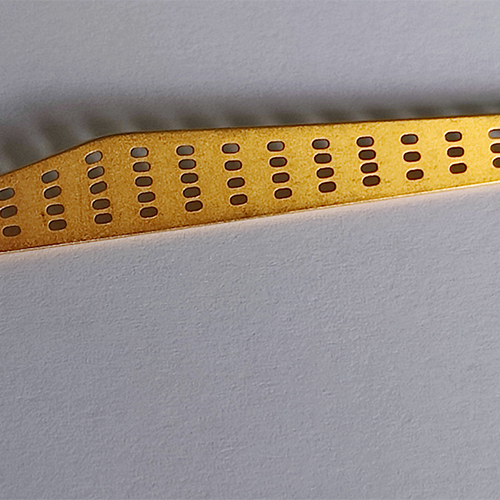

- Extremely high precision, up to +/-0.01mm accuracy, meeting the assembly requirements of different products. The thinner the material, the higher the accuracy control. We can process metal materials as thin as 0.02mm thick, up to 1mm thick, and can provide batch production and processing. And the quality control is strict and stable, the batch is clear.

- Products with complex shapes can also be etched without additional cost. Miniaturization and diversification are also available. The opportunity to realize customized services for different customers at home and abroad. Rather than just making high-volume products. We have a special engineering team for sample making, which can realize fast delivery of small batches of products. At the same time, the quality can be guaranteed.

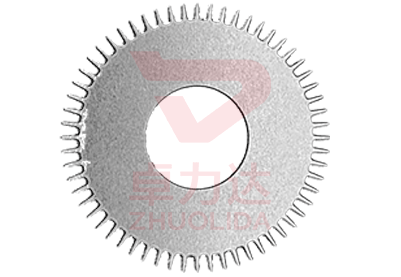

- There are no burrs, pressure points and deformation. The material properties and the function of the product will not be affected, especially for products with surface assembly requirements and smoothness requirements. Zhuolida etching processing solves various deficiencies in stamping, wire cutting and laser cutting processing. At the same time, the accuracy can meet the requirements of the product, even better than the above-mentioned several processes, and has irreplaceability.

- Thick and thin materials can be processed in the same way to meet the requirements of different assembly components. Of course, this situation is also relative, and this etching process is within the allowable range for thick and thin materials.

- Almost all metals can be etched, and there are no restrictions on various pattern designs. For particularly fine patterns, the etching process can also provide a good solution. Different metal materials require different chemical formulations. For example: rare metals: molybdenum, etc., can also be etched. The limit of pattern adding is wider than that of stamping, and the ability of deep processing is stronger. It is very suitable for processing with precision instruments, automobile engine filters, electrical appliances, camera components, etc.

- Manufacture metal parts that cannot be completed by various mechanical processing. Stamping and laser cannot complete the processing of fine and ultra-thin materials, and etching is easier to deal with.

Product advantages

- The coating fixture is a device for double-sided sputtering of quartz crystals or wafers. It can also be called a mask fixture, which including a vacuum chamber, a vacuum pumping unit, a workpiece holder, a magnetron sputtering target, a radio frequency plasma cleaner and an inert gas inflator.

- The vacuum pumping unit and the inert gas inflator are respectively connected to the vacuum cavity, and the feature is that a workpiece frame is arranged in the vacuum cavity, the workpiece frame can rotate, and a flip-able substrate is installed on the workpiece frame. A rack, the substrate rack is provided with a loading disk, the loading disk is provided with a quartz crystal sheet and a mask sheet, and at least two magnetron sputtering targets with a film cover are arranged on one side of the workpiece holder.

- A radio frequency plasma online cleaner is set on the other side, one of the magnetron sputtering targets is a transition layer sputtering target, and the other magnetron sputtering targets are electrode layer sputtering targets.

- The overall thickness of the mask fixture is usually more than 1.0mm, and there are cavities of different shapes and depths on both sides. It is usually etched in layers, and then the boards are bonded together by vacuum diffusion welding.

Customer we are doing our best to provide our bestservices to our customers with competitivetech solutions and high quality products,Zhuolida has won wide recognition from ourcustomers in all kinds of industry, andthis have laid a solid foundation for Zhuolida to be an leading brand in etchingindustry in China and a reputablemanufacturer |  |

| Technology Zhuolida is an etching factory in China with varietiesof process, our company process techniques includechemical etching, laser cutting, EDM, stampingelectroforming, electroplating, electrophoresis. |

Enviroment We have self-built sewage treatment system,the wastewater reuse rate reaches 40% |  |

Related products