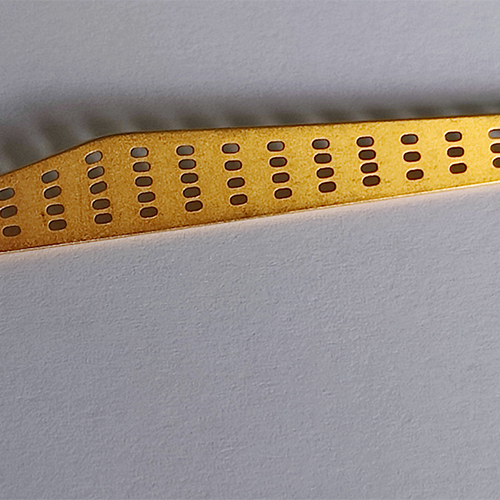

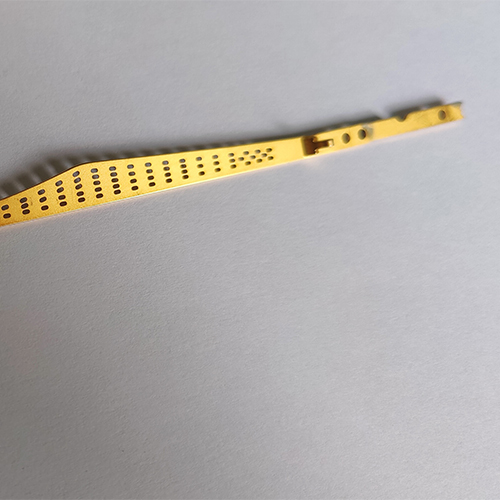

Spectacle frame etching

- Suitable for glasses worn in daily work and life

- Spectacle frames are made of high-precision, high-hardness metal materials. Spectacle frames are an important part of glasses. They mainly play the role of supporting spectacle lenses. Spectacle frames with beautiful appearance can also play an aesthetic role. Materials mainly include metal, plastic or resin, natural materials, etc. According to the style, it can be divided into full frame, half frame, frameless and other types.

The metal materials used for spectacle frames are copper alloys, nickel alloys and precious metals.

It is required to have certain hardness, softness, elasticity, wear resistance, corrosion resistance, light weight, luster and good color, etc. Therefore, the metal materials used to make spectacle frames are almost all alloys or used after metal surface processing.

1.International Certificate: The company has passed ISO9001 international quality certification, ISO14001 environmental management system certification, IATF-16949 automotive quality management system certification (raw material inspection + process inspection + shipment inspection + heavy quality inspection, so product quality is guaranteed. Cooperating with major domestic manufacturers, the yield rate far exceeds peer standard, with stable, high-quality raw material purchase channels.

2.Sample production: Equipped with a sample production team, within three working days.

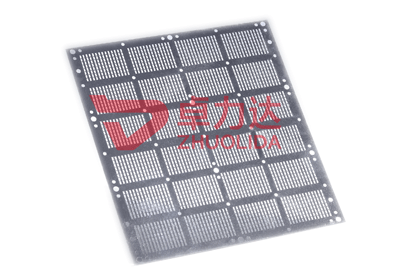

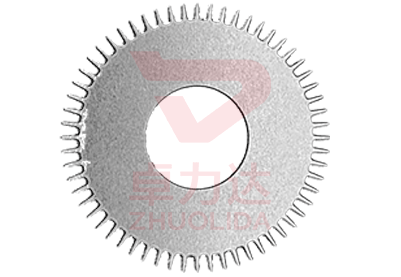

3.Advanced Technology: Our company has 3 major manufacturing bases in Shenzhen, Nantong and Kunshan, with a strong technical team (8 senior R&D engineers, 16 engineers, 20 technicians). The company has the etching line of CHEMCUT in the United States, and the photoplotter in Israel , French AUTOMA automatic roll-to-roll exposure machine and other internationally renowned advanced production equipment provide a rigid guarantee for production stability, and satisfy spectacle frame etching.In addition to production capacity, it provides various metal surface treatment services.

4.Delivery method:24-hour uninterrupted delivery (delivered by truck driver) in a safe, beautiful, and environmentally friendly packaging method. If you need express delivery, it can arrive within 48 hours. The express company that cooperates with our company is SF Express.

5.After-sales service:We have production inspection and quality quadratic imager inspection before shipment and standard process management to ensure that the products shipped to customers are qualified. If customers have objections to the product, our company will make processing advice within 12 hours.

6.Green production: We have obtained national environmental protection approval and dirty discharge permit. Our self-built sewage treatment system 24-hour re-line monitoring and liquid medicine regeneration cycle system has ensured the stability of the liquid medicine, improved the yield rate, made the liquid medicine recycle, and truly achieved environmental protection.

Customer we are doing our best to provide our bestservices to our customers with competitivetech solutions and high quality products,Zhuolida has won wide recognition from ourcustomers in all kinds of industry, andthis have laid a solid foundation for Zhuolida to be an leading brand in etchingindustry in China and a reputablemanufacturer |  |

| Technology Zhuolida is an etching factory in China with varietiesof process, our company process techniques includechemical etching, laser cutting, EDM, stampingelectroforming, electroplating, electrophoresis. |

Enviroment We have self-built sewage treatment system,the wastewater reuse rate reaches 40% |  |