Sealed cover plate

- Mobile phone sealed cover plate

- precision instrument sealed cover plate

- Chemical etching can be changed according to the designer's design requirements, with low cost and short cycle.

- New product etching design and development are flexible and low cost. The metal surface can be semi-etched and engraved with the public LOGO to realize the birth of the brand.

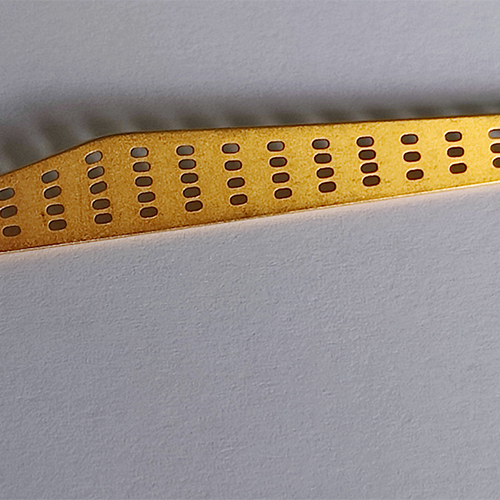

- The precision is extremely high, and the precision can be +/-0.01mm, which can meet the assembly requirements of different products. The thinner the material, the higher the precision control. We can batch process metal materials as thin as 0.02mm and as thick as 1mm. The production and processing quality is stable, the batch is clear, and the quality control system is strict.

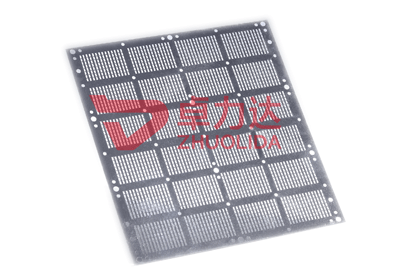

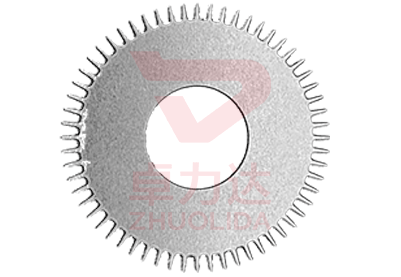

- Products with complex shapes can also be etched at no additional cost. At the same time ,we can also deal with miniaturization and diversification of products. It has realized customized services for different customers in Japan and abroad several times. We not only do high volume products, but we have a dedicated sample manufacturing engineering group to achieve fast delivery of small batches while maintaining quality.

- No burrs, indentations, no deformation of the product, no change in material properties, and no effect on product functions. Especially for products with surface assembly requirements and smoothness requirements, Zhuolida etching process solves various shortcomings of punching wire cutting and laser cutting processes. At the same time, the precision can meet the product requirements, even better than the above-mentioned process, which is irreplaceable.

- Whether it is thick material or thin material, we can process it equally well to meet the requirements of different assembly parts. Of course, this situation is also relative. This etching process for thick and thin materials is intended to be within the allowable range.

- Almost all metals can be etched, and there is no limit to various pattern designs. For particularly fine patterns, the etching process can also provide a good solution. Different metal materials require different chemical formulations. For example: rare metals: molybdenum, etc., can also be etched well. Compared with stamping and patterning, it has a wider range and stronger deep processing capabilities. It is very suitable for processing precision instruments, automotive engine filters, electrical appliances, and camera parts.

- We manufacture a variety of metal parts that cannot be done by machining. Stamping and lasers cannot handle fine, ultra-thin materials, and etching is easier to handle.

1.International Certificate: The company has passed ISO9001 international quality certification, ISO14001 environmental management system certification, IATF-16949 automotive quality management system certification (raw material inspection + process inspection + shipment inspection + heavy quality inspection, so product quality is guaranteed. Cooperating with major domestic manufacturers, the yield rate far exceeds peer standard, with stable, high-quality raw material purchase channels.

2.Sample production: Equipped with a sample production team, within three working days.

3.Advanced equipment: Our company has 3 major manufacturing bases in Shenzhen, Nantong and Kunshan, with a strong technical team (8 senior R&D engineers, 16 engineers, 20 technicians). The company has the etching line of CHEMCUT in the United States, and the photoplotter in Israel , French AUTOMA automatic roll-to-roll exposure machine and other internationally renowned advanced production equipment provide a rigid guarantee for production stability.

4.Delivery method: 24-hour uninterrupted delivery (delivered by truck driver) in a safe, beautiful, and environmentally friendly packaging method. If you need express delivery, it can arrive within 48 hours. The express company that cooperates with our company is SF Express.

5.After-sales service: We have production inspection and quality quadratic imager inspection before shipment and standard process management to ensure that the products shipped to customers are qualified. If customers have objections to the product, our company will make processing advice within 12 hours.

6.Green production: We have obtained national environmental protection approval and dirty discharge permit. Our self-built sewage treatment system 24-hour re-line monitoring and liquid medicine regeneration cycle system has ensured the stability of the liquid medicine, improved the yield rate, made the liquid medicine recycle, and truly achieved environmental protection.

Customer we are doing our best to provide our bestservices to our customers with competitivetech solutions and high quality products,Zhuolida has won wide recognition from ourcustomers in all kinds of industry, andthis have laid a solid foundation for Zhuolida to be an leading brand in etchingindustry in China and a reputablemanufacturer |  |

| Technology Zhuolida is an etching factory in China with varietiesof process, our company process techniques includechemical etching, laser cutting, EDM, stampingelectroforming, electroplating, electrophoresis. |

Enviroment We have self-built sewage treatment system,the wastewater reuse rate reaches 40% |  |