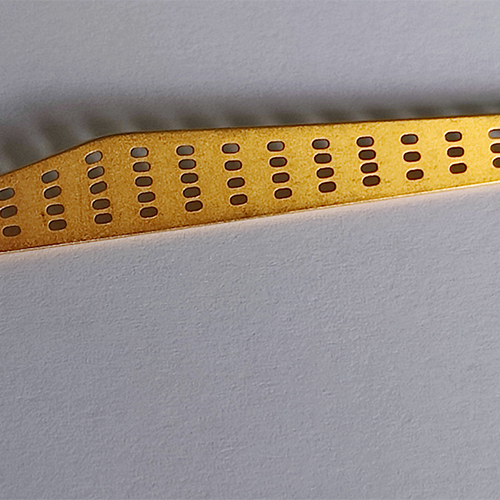

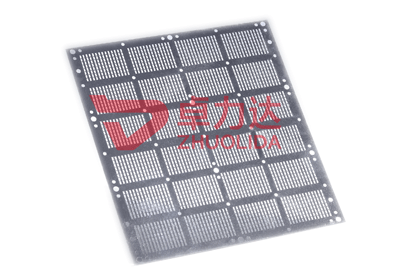

Semiconductor lead frame

- Integrated circuit chip carrier

Product name: | Semiconductor lead frame |

Material Material: | C194Copper, Red Copper, Phosphor Bronze,KFC、7025、TAMAC-15、PMC-90 |

Material Thickness (Metric): | 0.05mm,0.08mm,0.09mm,0.1mm,0.15mm,0.2mm,0.3mm |

Product Usage: | Semiconductor lead frameIt is the chip carrier of integrated circuits. It is a kind of electrical connection between the lead-out end of the internal circuit of the chip and the external lead by means of bonding materials (gold wire, aluminum wire, copper wire). Key structural components that form electrical circuits. |

Features: | |

Product price: | Determined according to material thickness, accuracy requirements, and mass production quantity. |

Etching capability: | Can be produced in large batches, and up to 1000 square meters. |

Samples provided: | Pay for proofing,make sample need three days,the fatest samples can be produced within 24 hours. |

Mass production time: | Produced within 1 week to 15 days, can be arranged by batch quantity |

Product testing and after-sales: | Two-dimensional, precise inspection of imaging equipment, 24-hour service 0755-2708-8292 |

Semiconductor lead frame etching characteristics | |

1.Low mold cost and short cycle time for the production of the template. Products can be changed according to the customer's design requirements. | |

2.Metal half-carving can be realized, and company LOGO can be engraved to realize branding. | |

3. Extremely high precision, up to +/-0.0075mm precision, meeting the assembly requirements of different products. | |

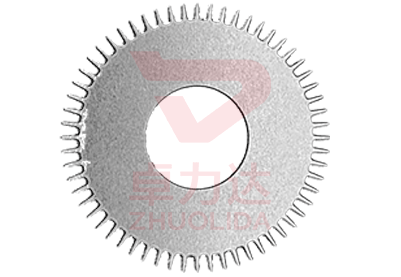

4. Products with complex shapes can also be etched without additional cost. | |

5. There are no burrs, pressure points and no deformation.The material properties and the function of the product will not be affected. | |

6. Thick and thin materials can be processed in the same way to meet the requirements of different assembly components. | |

7. Almost all metals can be etched, and there are no restrictions on various pattern designs. | |

8. Manufacture metal parts that cannot be completed by various mechanical processing. | |

Display diagram

1.International Certificate: The company has passed ISO9001 international quality certification, ISO14001 environmental management system certification, IATF-16949 automotive quality management system certification (raw material inspection + process inspection + shipment inspection, heavy quality inspection, product quality is guaranteed. Cooperating with major domestic manufacturers, the yield rate far exceeds Peer standard, with stable, high-quality raw material purchase channels.

2.Sample production: Equipped with a sample production team, within three working days.

3.Production base: Our company has 3 major manufacturing bases in Shenzhen, Nantong and Kunshan, with a daily output of 5000+㎡, strong technical force (8 senior R&D engineers, 16 engineers, 20 technicians), the company has the etching line of CHEMCUT in the United States, and the photoplotter in Israel , French AUTOMA automatic roll-to-roll exposure machine and other internationally renowned advanced production equipment provide a rigid guarantee for production stability.

4.Delivery method: Generally according to customer requirements, sub-carton plus spacer cardboard or fixed pad cardboard for concise, safe, 24-hour delivery. If you need fast distribution division, we will cooperate with the courier company SF or make direct delivery.

5.After-sales service: We have production inspection and quality quadratic imager inspection before shipment and standard process management to ensure that the products shipped to customers are qualified. If customers have objections to the product, our company will make processing advice within 12 hours.

6.Green production: We have obtained national environmental protection approval and dirty discharge permit. Our self-built sewage treatment system 24-hour re-line monitoring and liquid medicine regeneration cycle system has ensured the stability of the liquid medicine, improved the yield rate, made the liquid medicine recycle, and truly achieved environmental protection.

Shenzhen Zhuolida Electronics Co.We are a one-stop high-end precision etching solution provider, specializing in metal etching, precision metal etching, mesh etching, gasket etching, titanium etching, roll-to-roll etching, stainless steel etching processing and other businesses.Zhuolida all the Semiconductor leadframes The factory are after production inspection, quality inspection, warehouse verification, layers of control, quality is trustworthy!The company is set up in Shenzhen Fuyong Huafa Industrial Park , with a building area of more than 6,000 square meters, modern workshops and production and experimental and testing equipment.Key equipment includes: imported etching production line, constant temperature and humidity dust-free operation room, exposure machine, developing machine, secondary measuring instrument, automatic de-filming production line, etc.

Customer we are doing our best to provide our bestservices to our customers with competitivetech solutions and high quality products,Zhuolida has won wide recognition from ourcustomers in all kinds of industry, andthis have laid a solid foundation for Zhuolida to be an leading brand in etchingindustry in China and a reputablemanufacturer |  |

| Technology Zhuolida is an etching factory in China with varietiesof process, our company process techniques includechemical etching, laser cutting, EDM, stampingelectroforming, electroplating, electrophoresis. |

Enviroment We have self-built sewage treatment system,the wastewater reuse rate reaches 40% |  |

Zhuolida Offering:Semiconductor leadframes|Semiconductor leadframesEtching|Semiconductor lead frameEtching process

Shenzhen Zhuolida Electronics Co., Ltd. https://www.zldsk.com

Address:Block A3, Huafa Industrial Park, Fuyong Town, Fuyong, Shenzhen, China

Contacttel:0755-2708-8292