Etching hardware uses etching solution for etching process, which is an emerging chemical etching method to remove the protective film in the etched area by exposing the plate making and developing, and then contacting the chemical solution during the etching process to achieve the effect of dissolving corrosion to form a bump or hollow molding.

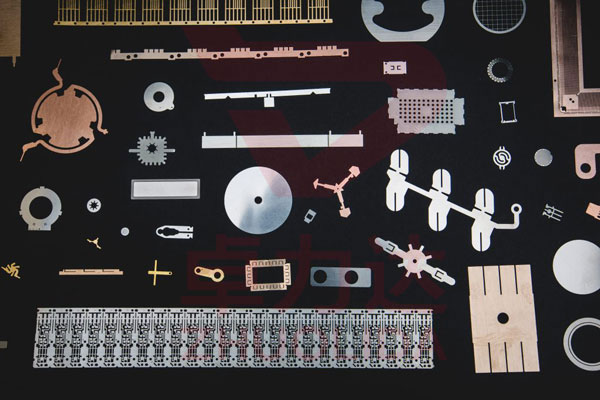

Conventional die stamping or wire or laser cutting can affect the material or product: such as changing the nature of the material, the flatness of the material, many difficult to handle burrs, residues, etc. In this case, etching process must be considered to solve the complex shape of the part processing. For example, very thin stainless steel mesh, through the hardware etching process of Zhuolida Electronics Factory can reduce the difficulty of forming and processing costs.

1、Finalize the graphics needed by the client on the computer.

2、Etching mask layer etching directly on the workpiece through software and high-end etching equipment.

3、Enter the etching process.

For very thin hardware originals, if the traditional etching process is used, it will easily lead to product deformation. However, Jolida hardware etching process can also perform precision hardware etching while ensuring that the product is not deformed.

In terms of processing technology, the complex hardware etching process is simplified and pollution is fundamentally eliminated. In terms of processing efficiency, the new etching process not only improves production efficiency, but also improves the quality of finished products. Therefore, the etching process of Zhuolida Electronics Factory will provide a boost to etched products in the future.