| 一、Current Status |  |

The rapid development of the consumer electronics industry, technology tends to be high, precise, sharp, short product life cycle, rapid replacement, fast market speed, multiple types, small batch, while product precision requirements tolerance within microns, the traditional manufacturing process can not meet this requirement. | |

| 二、Products | |

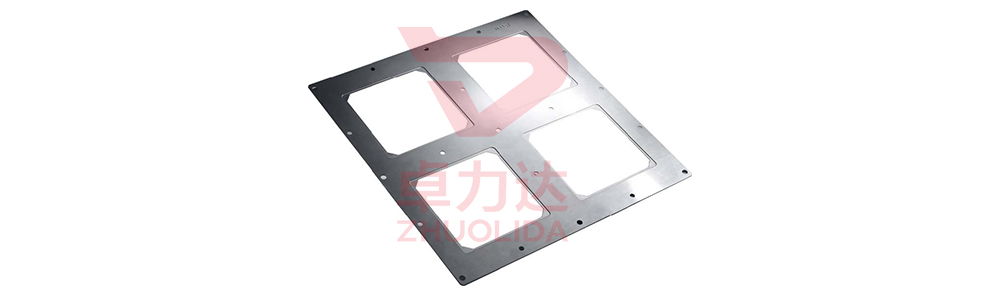

IC lead frame, sealed ceramic cover, code plate, copier charging grid, dust screen, insect screen for smoke alarm, contact sheet, spring sheet instrument panel, components of wiper carrier, brush carrier accessories. |

Audio equipment mesh Mobile phone handset mesh, loudspeaker mesh,headphone mesh, speaker screen mesh and other dust-proof or decoration mesh for audio equipments. |

|

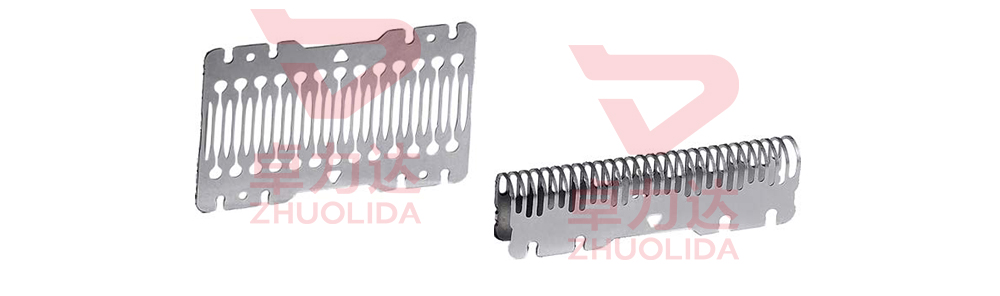

Reciprocating Cutter mesh Etching technology can process concave and convex reciprocating cutter mesh by using the design data, chart, and complex column,its positioning hole and assembly hole can be very accurate and the blade edge can be very sharp. |

|

half etch products Etching technology can be used in high-end watches and relative accessories that require reducing thickness. |

|

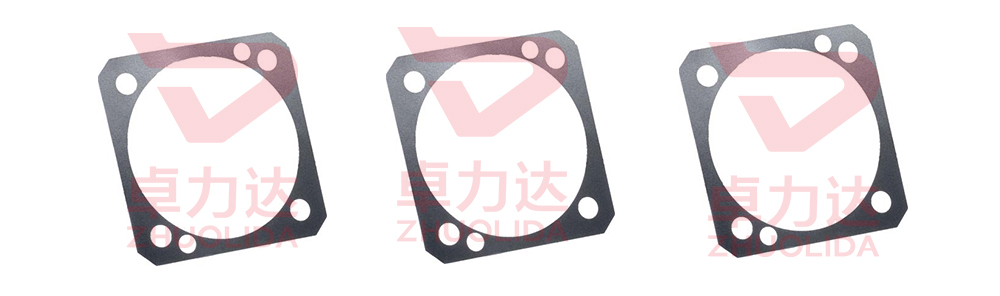

Precision shim It is made of high precision and high hardness sheet material. It is usually used in the adjustment and measurement of precision mold and precision hardware,or as cushion block, also known as die gasket or precision spacer. |

|