| 一、Current Status |  |

With the rapid development of minimally invasive surgery and other precision engineering, more and more tiny implanted parts are needed for the human body, and the miniaturization and precision are increasingly high. Prototype parts need to be low-cost and accuracy to ensure tolerances within microns, modify the prototype and short time of mass production. Through the digital module, the customer can improve or change the design at any time, avoiding high tooling costs and reducing production costs for the customer. | |

| 二、Products | |

Metal precision components for medical devices, grids for X-ray machines, specialized scalpel blades, blood and fluid filter components, precision implants, stents, pacemaker components, orthopedic pins, bone reconstruction components, blades, chassis parts, gaskets, fascial plate light, electrical encoders, gaskets, spacers, orifice plates, battery covers, clock seconds, grids, molecular sieves, optical components, optics, reticles, etc. |

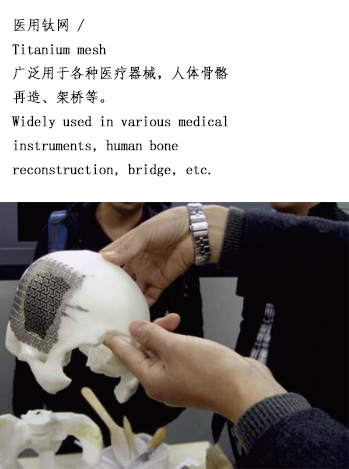

CT Grating It is widely used in medical CT imaging equipment. |

|

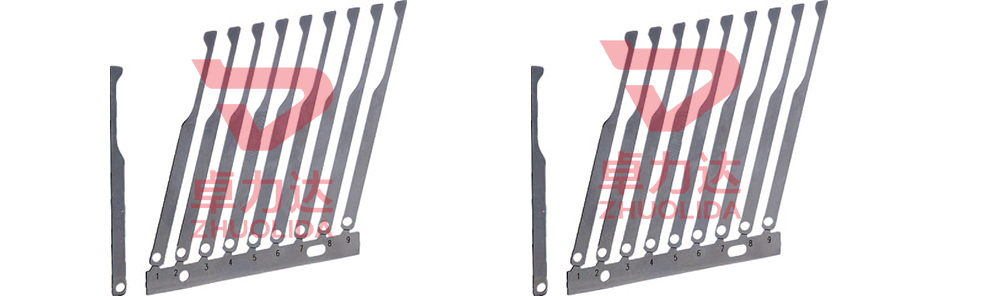

Layer Tear Gasket A piece of gasket is superimposed and bonded together to adjust the clearance and compensate the tolerance. The gasket thickness can be adjusted from 0.01 to 1.0. |

|

Surgical Blade Disposable minimally invasive surgical blade. |

|

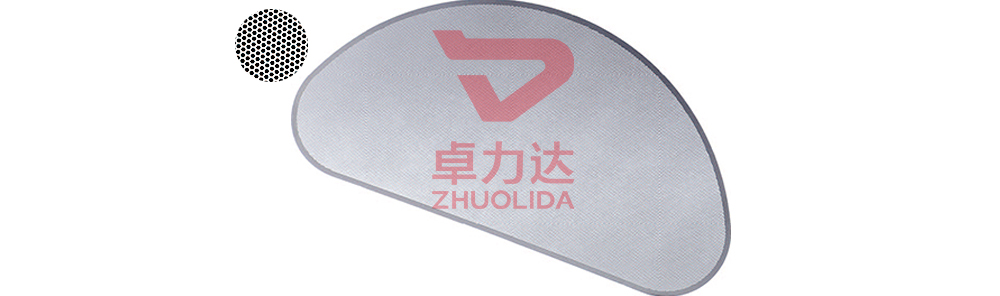

Microporous network Microporous mesh is a kind of high precision etching products with high tolerance, made by imported stainless steel SUS304 / 301 / 316. The thickness of metal material: 0.03mm-1.0mm. |

|