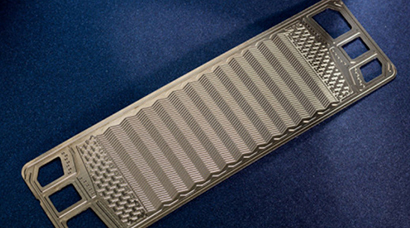

Fuel cell bipolar plates are mainly graphite, composite materials and metals. The bipolar plates should be made as thin as possible in the production process to reduce the current and heat conduction resistance, and their main function is to provide a gas flow channel to prevent the hydrogen in the closed gas chamber of the battery from passing in series with oxygen, and the series connection makes a current channel between the cathode and anode at home.

There are four ways to process metal bipolar plates.

Bipolar plate stamping: By stamping metal materials into runner plates, using welding and coating, dispensing to airtightness testing. Due to the high cost of stamping, the need to open the mold molding, stamping is easy to cause deformation therefore the use of etching process to complete.

Bipolar plate etching: bipolar plate etching process has no restrictions on design drawings, lower development costs, no need to open the mold need to do film, by etching bipolar plate can achieve half engraving, full engraving, LOGO, etc., high precision, micron-level tolerances can be achieved.

CNC machining of bipolar plate: The process of bipolar plate cannot be satisfied on the wire channel and the machining cost is high.

Bipolar plate laser: laser process processing bipolar plate on the processing range of a single, can not meet the requirements of half-engraved.