Stainless steel etchingThe process of burr-free, smooth surface of the product advantages, gradually popularized by the public preferred, in order to pursue product quality some products need to theStainless steel etchingThe surface is again processed on the process, such as microphone sandblasting, stainless steel galvanized copper, etc. So, what kinds of surface treatment processes we are exposed to?

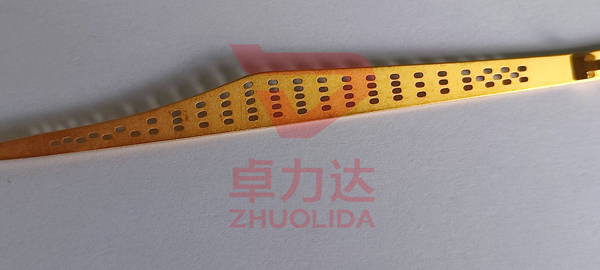

1、Electroplating, plating is a frequent contact on etched products, where plating can be done in coffee, black, bronze, rose, champagne gold, seven colors, etc.

2、Etching,Through the chemical method of corrosion out of a variety of patterns, the surface of the object in deep processing, such as in the local grain, brushed, embedded gold, local titanium gold and other kinds of complex technology processing. In the color: sky blue, titanium, green, bronze, teal, purple, etc., often used in everyday life in star hotels, hotels, hotels, hotels, hotels, etc.KTV、Large shopping malls, high-class entertainment venues, etc.

3、Sandblasting, color plating by sandblasting, different from other processes is sandblasting to take the diamond sand, suitable for architectural decoration, industrial decoration, equipment decoration and other stainless steel products on the series.

4、Embossing series, embossing is the process of processing the concave and convex pattern on the surface of stainless steel by mechanical equipment, suitable for elevator decoration, kitchenware, etc. The pattern form is various, so that the surface hardness, more wear-resistant, maintenance-free, anti-strike, anti-scratch.