Etching,it refers to etching, also known as photochemical etching, which refers to the removal of the protective touch of the corroded area and contact with a chemical solution to achieve the effect of dissolving corrosion and forming a concave or hollow molding. Etching processing technology can be divided into wet etching and dry etching.

Metal products need to be prepared before etching process:

1、Metal Etching ProcessingStains and oxide films on the surface should be thoroughly removed.

2、To remove the oxide film, we also need to choose a good etching solution according to the type of metal and the thickness of the film to ensure a clean surface.

3、It should be dry before screen printing. If there is water, it will also affect the adhesion of the ink, affect the subsequent pattern etching or even deformation, and affect the decorative effect.

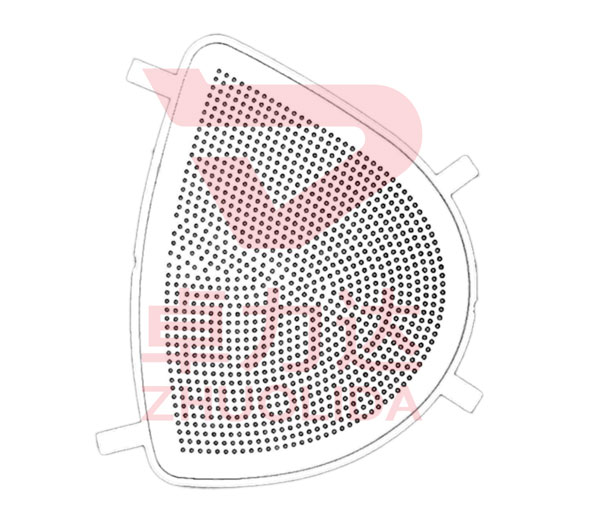

4、Screen printing should be made according to the printing needs of the standard pattern screen printing version. In the process of pattern decoration, screen printing mainly plays a protective role and should be coated with light glue several times to make thicker screen stencil to make good coverage performance and high definition of etched patterns.

EarlyEtching process technologyCan be used in the manufacture of copper plate, zinc plate and other printing intaglio-convex plate, also widely used to reduce the weight of the instrument panel, nameplate and traditional processing methods difficult to process the thin workpiece; after continuous improvement and process equipment development, can also be used in the aviation, machinery, chemical industry, especially the semiconductor process.EtchingIt is an indispensable technology.