Usually we understand the etching process is mainly metal materials and non-metallic materials, the current prevalent etching process are using chemical etching, also known as photochemical etching, acid, alkali, ferric chloride is the main influencing factors in the process of metal etching, the waste liquid generated during the process must be properly treated, not arbitrarily discharged. Zhuolida to establish a recycling environmental protection system, 24-hour monitoring of the wastewater generated for treatment, etching process needs to go through nine process steps, Zhuolida etching process can reduce labor costs, reduce processing time, reduce energy consumption and greatly improve production efficiency.

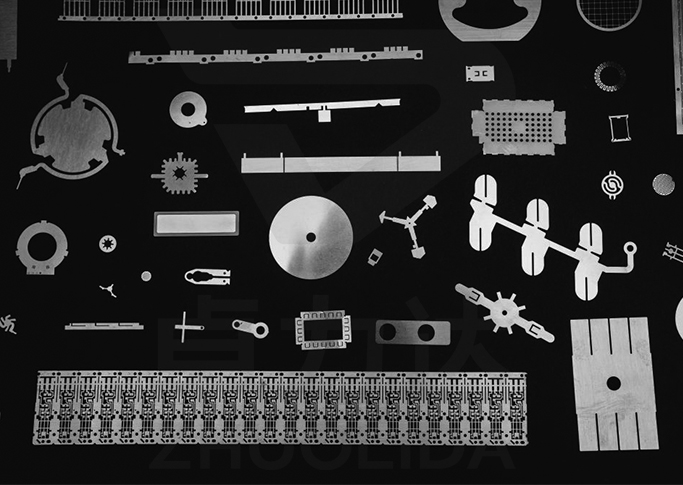

Etching processThe main areas are:

1.A variety of common home appliance applications, such as speaker screens, filters, code plates, gaskets, etc., and car speaker screens in the smart car manufacturing field are completed by etching.;

2.Etching process is an inaccessible process in modern technology, especially in the field of precision instruments, such as lead frames, medical device filters.;

3.In the general civil field, more and more electronic housings, instrument panels, nameplates, etc. are using chemical etching processing methods to improve the high precision of products and enhance the competitiveness of products in the market.

In the process of product design and manufacturing, we adopt quantitative standards and use reasonable profit margins to help our customers achieve their original design intentions. Only the customer's design can be perfectly realized and superior to similar products in the existing market, and can lay a solid foundation for the customer's product to eventually win the market.