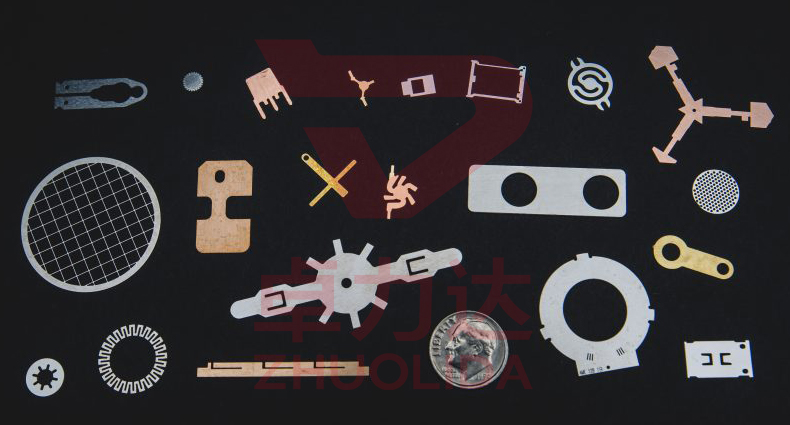

Precision hardware etching processIt is usually some metal parts with complex shapes and categories but high precision requirements. As many mechanical processing is difficult to complete or the processing cost is too high, etching processing is used. So, what is the method of etching processing?

Zhuolida etching process focuses on precision hardware etching processing, which simplifies the etching process and improves the efficiency of product etching processing. It can effectively avoid jagged line pattern edges, pattern leakage, blurred edges, pattern deformation and other quality problems that easily occur in the traditional process, and improve the finished product rate.

ThisPrecision hardware etching processWhat are the characteristics of the

1、Metal hardware processed in complex shapes, such as very thin stainless steel mesh, which requires the use of etching processes to reduce costs and molding difficulties.

2、For thinner hardware, stamping can cause distortion of the metal and etching can ensure flatness. In addition, thin hardware is easier to control the accuracy;

3、Etching does not change the properties of the hardware material such as hardness, strength, and physical properties of the molding;

4、Etched hardware with smooth surface and no rolled edges。

Precision hardware etching processVarious specifications of metal hardware can be processed, the main materials are stainless steel, titanium alloy, copper, aluminum and other materials, suitable for the sheet within 0.03MM-2.0MM thickness, the minimum tolerance can be controlled to 0.0075mm.