According to media reports, China's military budget for 2022 is 1.45 trillion yuan, an increase of 7.1% year-on-year, and defense military spending is expected to reach 1.8 trillion yuan by 2025, with weapons and equipment accounting for about 1/3 of the total cost. The State Council issued the "Made in China 2025", China's defense industry will become the main force of the manufacturing power, of which, 85% of modern military core technologies used in civilian key technologies, more than 80% of civilian key technologies are also successfully used for military purposes, in the defense industry industry proliferation and promotion, military-civilian integration to enhance China's manufacturing, but also actively promote the innovation of high-tech industry has a great The military-civilian integration has a great driving effect on the innovation of high-tech industry.

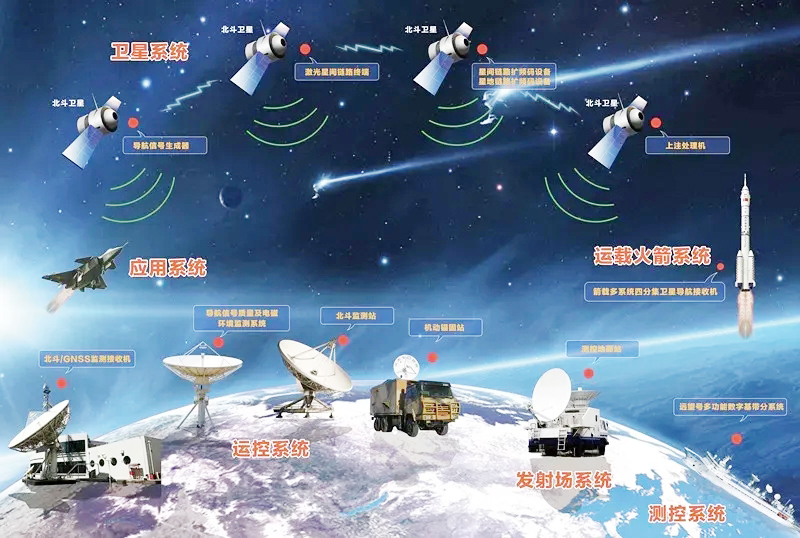

The military industry mainly involves six major fields: aerospace, shipping, electronic components, weapons and equipment and nuclear industry. China's entire military industry from the upstream of raw materials, components, to the middle of the subsystem, to the downstream of the mainframe plant, basically realized the entire industry chain. From the traditional multiple work, high energy consumption, high consumption of materials to the modernization of high-precision, micro-tolerance transformation process, etching process gradually play its vital advantages.

The emphasis on quality in aerospace and defense engineering runs throughout the production and development of products. Shenzhen Zhuolida Electronics Co., Ltd. already has rich practical experience in manufacturing safety-critical systems for components, and is capable of processing various special materials for aviation, which involve high-strength stainless steel and heat-resistant steel, aluminum, aluminum bronze, aluminum lithium, beryllium copper, phosphor bronze, nickel, chromium-titanium heat-resistant alloy, and heat-resistant hot nickel-chromium-iron alloy. In response to the demand for high precision and micron-level tolerances in the aviation and military fields, Jolida Electronics has passed ISO9001 international quality system certification, ISO14001 environmental management system certification, and IATF-16949 automotive quality management system certification, and is a comprehensive solution provider integrating precision metal etching, electroplating, electrophoresis, anodizing, precision electroforming, and vacuum diffusion welding. Among them, through the process of etching and surface black plating, practice applications in a variety of weapons of infrared tracking and targeting of military targets. The uniform temperature plate or runner plate is widely used in metallurgy, petroleum, chemical industry, food, pharmaceutical, shipping, textile, paper and other industries; light apparatus applied to machine tools and modern processing centers and measuring instruments, etc. The use of these products, confirmed the Zhuolida etching process in the technology of deep research and continuous exploration for China's aviation, military equipment, high-precision, micron-level success to help.