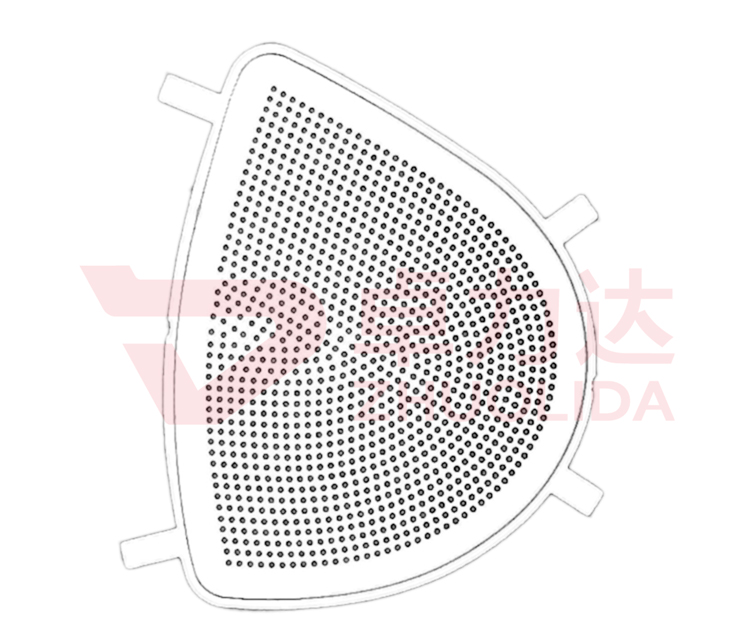

Speaker mesh cover is usually commonly used in speakers, speakers outside to play the role of dust filtering, decoration and protection of the internal structure of the speaker, the current contact is more headphones, car speakers, stereo speakers, etc.. The process used for stainless steel speaker grilles are as follows:

1、Stainless steel filter cover stamping process, stamping process is a more widely used processing method, stamping process out of the mesh cover appearance, grid aperture, graphics and other requirements is not very high, the cost of opening the mold is more expensive, commonly used in three-dimensional speakers, for high precision thickness on the stamping process can not reach the level.

2、Stainless steel filter cover laser process, laser process manufacturing on the relatively slow, batch production capacity can not be achieved, the price is not cheap.

3、Stainless steel filter etching process. Etching process circumvents the shortcomings of laser, stamping processing, using metal film molds through exposure, development, chemical etching process, the use of chemical etching solution etching stainless steel, etching processing accuracy can be pursued 0.03MM-2MM thickness, processing of hole shape, pattern can be arbitrarily designed, the edge of the product etching out no burr, no deformation, do not change the characteristics of the material itself, porous aperture By using the chemical etching process, we can maintain the uniform size of the product aperture.