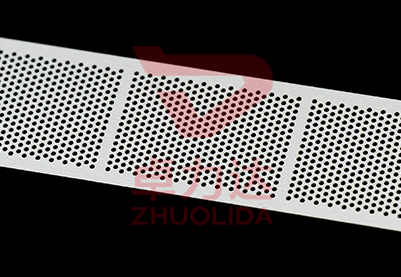

Etching, we usually also call photochemical etching, that is, the production of metal film plate, by laminating the film, and then after exposure, development process, the protective film to be etched area removed, in the etching so that the metal contact chemical solution, the use of metal film positive graphics through the chemical flooding from both sides of the grinding to achieve the effect of dissolution corrosion, the formation of concave and convex or hollow molding effect. The part of the film lamination protection is not chemically etched away, while the part that needs to be etched forms the pattern in the dissolution of the chemical. Chemical etching is very specific, is specifically referred to controlled corrosion, is metal parts through chemical methods for a controlled parts processing method.

Etching process is as follows: 1, FILM (CAD drawing design)-2, raw material preparation-3, pre-treatment (cleaning)-4, DRY FILM lamination (lamination)-exposure-development-drying-etching-peeling (shedding operation)-check packaging, out of storage

Advantages through the etching process.

(一) Low mold opening cost and short cycle time for template making

(二) Flexible change of new product etching design and development, low cost

(三) No burr, pressure point, no product deformation

(四) Very high precision, the thinner the material, the higher the precision

(五) miniaturization, diversification and complex shape products can be completed quickly

(六) Can achieve metal half-engraving, to achieve branding processing

(七) Thick and thin materials can be processed equally

(八) The manufacture of various types of metal parts that cannot be completed by mechanical processing

(九) Almost all metals can be etched, and there is no restriction on the design of various patterns