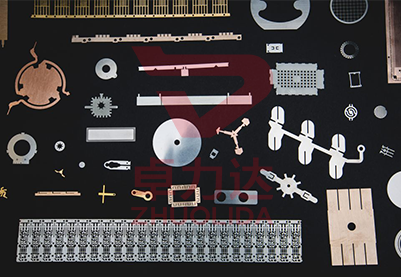

Micro-hole processing is a frequent problem in the metal processing process, due to its different materials, thickness, the degree of difficulty is also different, the selection of the process will also be different. Stainless steel micro-hole processing is mainly related to the force surface, processing aperture and depth parameters, so the choice of different process means will produce different results, which is why there are high and low quotes in the selection process. At present, the conventional methods of stainless steel micro-hole processing are mainly the following.

(1)Laser processing: laser processing of widely used in electronic products, multilayer circuit board welding, drilling of metal substrates, linear cutting field. It has the characteristics of low cost and reliable processing quality, but in the precision metal substrates and mesh, the way of laser processing is relatively violent heating, especially in the semiconductor products lead frame, packaging cover products, due to the thickness and area of the product is relatively thin and small, through the laser processing method is easy to destroy the original characteristics of the material, the surface will produce a sense of scorching, the phenomenon of blackening, and not easy to clean up. For the general requirements of less demanding products on the laser processing method is also a better choice.

(2)Linear cutting: The linear cutting method is widely used in the field of slow walking wire, batch production on the linear cutting price is relatively high, while not well maintain the original characteristics of the product, the use of thinner product material is prone to deformation.

(3)Etching process: etching process belongs to the chemical etching, that is, photochemical etching, is through the metal material on the part that does not need chemical corrosion to increase the protective film, to be corroded part of the exposure after exposure, development, etching to dissolve the formation of concave and convex or hollow molding effect. Etching process is widely used on high precision products, etching process can make the metal surface flat, burr-free, complex graphics or aperture dense consideration, etching process to meet the advantages of short processing cycle, low cost.

(4)EDM micro-hole processing: The disadvantage of EDM micro-hole processing is that for the requirement to do intensive aperture in the material can not meet the purpose of mass production, and the cost is relatively high, mainly used in the hole force on the smaller material, such as microcomputer machinery and equipment, optical instruments and other parts processing on flexible application.

The above are several methods for stainless steel micro-hole processing, if the need for micro-hole processing then the above methods can be referred to choose the best solution.