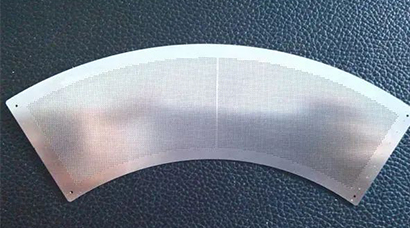

Thin base material filter sheet due to its relatively small precision and tolerance, and micron level requirements are also high, in the pursuit of the process is extremely demanding, the filter sheet using the processing method is chemical etching micro-groove and EDM linear cutting processing shape, which also uses laser processing method in the perforation process, but linear cutting and laser perforation technology will appear burnt sense, the smoothness of the product is not high, chemical etching France within the machine On will not be high precision, due to the reason of chemicals on the environment will produce pollution, the actual reality of the problem, want to solve the accuracy and pollution generated in the process of chemical corrosion, can be imported through higher precision foreign machines, and chemicals can establish a new cycle of environmental protection system, as much as to achieve the purpose of protecting the environment also did a favorable cycle. The oil core screen in the field of smart cars is the way of etching.

Liquid filter is a spacecraft two-component propulsion system for filtering liquid propellant, using a thin substrate filter with micro grooves, material thickness of 0.06mm titanium foil, the surface has a petal-shaped micro grooves, thin substrate filter can choose etching process, etching thin substrate filter can meet the thickness of 0.03mm, thin substrate filter etched products without burr, the surface is relatively smooth The products etched from thin substrate filters are burr-free and have a relatively smooth surface.