Cold rolled sheet perforated mesh is widely used in curtain wall panels, speaker panels, filter screens, anechoic and sound-absorbing panels, filter screens, insect screens, kitchen utensils, etc. Cold rolled sheets of various thicknesses are punched on CNC machine tools in different staggered or direct arrangements. The surface treatment of cold rolled plate perforated mesh can be galvanized, sprayed, painted and other anti-corrosion treatment to make the surface of the product not easy to rust, beautiful and durable, corrosion-resistant and high temperature resistant characteristics.

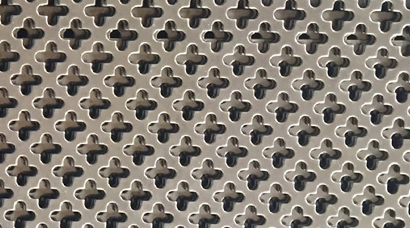

The material of cold rolled plate perforated mesh is generally galvanized steel, hot and cold rolled plate, copper plate, nickel plate, stainless steel plate and aluminum alloy plate, and the thickness of the material can be 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm and so on. Can be processed into different styles of hole type, such as round hole, long strip, pentagonal hole, octagonal hole, round hole, anisotropic hole, louvered hole and plum blossom hole, etc. The size range of the aperture is 1.0mm-200mm, which basically can meet the needs of the use of conventional environment. But if in the use of precision filters and precision dust screen, this cold-rolled plate perforated mesh will be in a specific environment defects, due to stamping will lead to product burr, compared to laser welding and laser aperture of the black spot, can not be used in a particularly precise instrument, in order to meet the needs of this specific product, etching process is the preferred means of technology, through etching out of the product without burr surface smooth, the product can be used to meet the needs of this specific product. The speaker mesh on the car, the filter mesh on the car filter, the insect screen in the smart product, the dust screen in the alarm are all done by means of the etching process.