Metal production and processing process will touch die-cutting materials, die-cutting equipment, knife die, die-cutting process, etc., of which the knife die is a typical representative of the die-cutting industry, so through the laser knife die and etching knife die process between what differences exist?

Laser knife die by using professional equipment to process the blade into a variety of different shapes, and then installed into the slit with the laser cut out of the template or PVC plastic plate to form a die-cutting knife die. It is often applied to industries such as printing and packaging and electronic materials.

The following features are available through laser tooling compared to traditional machining processes.

1. Higher production efficiency: Since the laser tooling method is designed by using professional software on the computer instead of traditional manual drawing, it makes the drawing work simple and clear, which greatly reduces the drawbacks caused by the traditional process.

2. The process of production is higher in precision: with CNC fully automatic operation, it is able to reach ±0.1mm in precision, cut out products with even gaps, and the size that can be achieved in precision far exceeds the great errors produced in the traditional hand-made process.

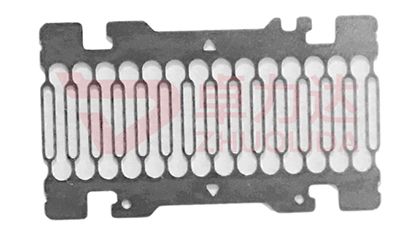

The etching die is made of high carbon steel plate material, which is exposed on the etching machine by using the film and steel plate lamination, and then the excess is developed and etched off, and the blade is made for surface treatment by the engraving and milling mechanism.

The advantages between etching dies and laser dies are as follows.

1. High precision by etched die, smooth lines, high repeatability and no burr at the product corners.

2. The tolerance of the etched die can reach ±0.01mm; the same die is made repeatedly with very small error.

3. Facing complex workpieces, the same mold is able to realize full-break, half-break, toothed knife, folding line and other molding methods.