With the continuous extension of science and technology, the medical device sector mainly includes high-value consumables (cardiovascular, orthopedic, oral, etc.), medical devices (imaging equipment, endoscopy, life support equipment, etc.), and in vitro diagnostics (biochemical, immunological, molecular diagnostics, etc.). According to Evaluatemedtech data, the global medical device market size soared to 477.4 billion yuan at a compound annual growth rate of 4.06%. China's medical device Blue Book data market size of nearly RMB 800 billion.

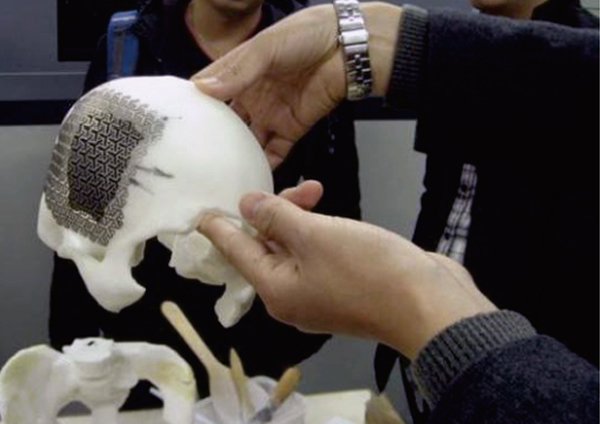

Medical tiny precision equipment is the most embodied etching process in the medical precision field of use, such as medical titanium mesh, through the titanium material etched medical titanium mesh is mainly used for a variety of medical devices, human skeletal reconstruction, bridging, etc., the pursuit of extreme micron-level tolerance, the smallest control of the aperture can be ± 0.01MM, the thickness of the extreme up to 0.03MM-1.0MM. medical titanium mesh is mainly through the metal after pretreatment After the plate is exposed and developed, the protective film of the etched area is removed, so that the metal is in contact with the chemical solution, and the dissolution of corrosion is achieved by using two positive shapes through the chemical grinding of both sides to form the effect of concave and convex or hollow molding. The materials involved are mainly imported stainless steel, aluminum, copper, etc. Compared with the traditional stamping process, stamped metal filters will make the material burr rolled edge, high processing costs, and the material is also prone to deformation, while etching can make the material burr-free, no rolled edge, accurate appearance and relatively low development costs.

Zhuolida etching has advanced production equipment such as the etching line of CHEMCUT from the United States, the light painting machine from Israel, and the automatic roll-to-roll exposure machine of AUTOMA from France, which can solve the precision in medical devices up to the tolerance micron level, and its products are involved in metal precision components for medical devices, grids for X-ray machines, special scalpel blades, blood and fluid filter components, precision implants, stents cardiac pacemaker components, orthopedic pins, bone reconstruction components, blades, chassis parts, gaskets, fascial plates light, electrical encoders, gaskets, spacers, orifice plates, battery covers, clock seconds, grids, molecular sieves, optical components, optics, reticles, and other successful practices.