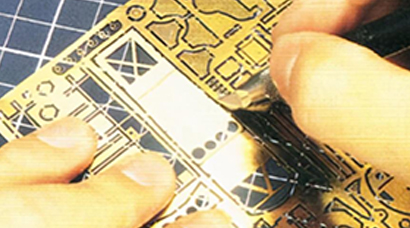

Stainless steel etching process is through the chemical agent ferric chloride strong oxidation of stainless steel corrosion to form a different pattern, the professional call photochemical etching process, photochemical etching process is divided into dry etching process and wet etching process in two ways. By making plates of stainless steel after exposure and development, the area of stainless steel to be etched to remove the protective film, through the chemical corrosion of stainless steel, the use of two positive graphics through the chemical grinding from both sides to achieve the effect of dissolving corrosion, the formation of bump or hollow molding effect. Simple understanding of how to transfer the pattern of the film to photographic paper, and etching process, it is the film for the metal film, more complex patterns need more metal film laminated together, the use of exposure machine for exposure to transfer the pattern to the metal material with blue film protection, and then chemically etched so as to form the pattern.

Stainless steel etching process flow: cleaning - roll coating - exposure - development - etching - de-filming - cleaning - testing.

Zhuo Li Da stainless steel corrosion processing plant successfully practiced the use of a wide range of fields, including EMC bracket is mainly used in LED medium and high power lamp beads packaging, semiconductor solutions on integrated circuits on the lead frame; 5G field for unmanned LIDAR signal coding ring, for cell phones, notebooks, car stretch screen, scroll screen and other folding screen, flexible screen, for cell phones, notebooks and other electronic products fast Heat dissipation VC homogeneous plate; medical field is widely used in major brands of medical CT imaging equipment CT grating, layer tear shims mainly play a gap adjustment, compensation tolerance, microporous mesh stainless steel corrosion processing is a common process, which in precision parts, etching precision high tolerance small, imported stainless steel, etc.; precision filters used in precision filtration, vacuum cleaners, audio, household appliances and other electronic products.